Specs at a glance

-

Accuracy

+/- 2mm + 0.17% of measured distance

-

Process temperature

-40 °C ... 105 °C

(-40 °F ... 221 °F)

30 min: 135 °C / 275 °F) -

Process pressure / max. overpressure limit

0.7 bar ... 4 bar abs

(10 psi ... 58 psi) -

Max. measurement distance

Liquids: 10 m (33 ft),

Solids: 5 m (16 ft) -

Main wetted parts

316L (fully welded IP68 / NEMA 6P)

Field of application

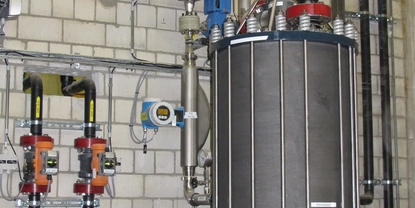

The FDU91F ultrasonic sensor for continuous, non-contact and maintenance-free level measurement of fluids, pastes, sludges and powdery to coarse bulk materials. Also for flow measurement in open channels and at weirs. Measurement is unaffected by dielectric constant, density or humidity and also unaffected by build-up due to the self-cleaning effect of sensors. Fully welded 316L with hygienic process connection available. Maximum measuring range in liquids 10m (33ft), solids 5m (16ft).

Continuous, non-contact level measurement of fluids and bulk materials in silos, on belts, stockpiles or in crushers. Also for flow measurement in open channels and at weirs. Used in measurements in low structural heights.

Process connections: Thread, Tri-Clamp

Temperature: -40 to +105°C (-40 to +221°F)

Pressure: 0.7 to 4bar (10 to 58psi)

Max. measuring range: Liquids 10m (33ft), solids 5m (16ft)

Blocking distance: 0.3m (1ft)

International explosion protection certificates, hygienic certificates

Benefits

Integrated temperature sensor for Time-of-Flight correction. Accurate measurements are possible, even if temperature changes are present

Hermetically welded sensors (316L, 1.4404, 1.4435) for highest chemical resistance

Suited for rough ambient conditions thanks to separate installation from the transmitter

(up to 300m)Reduced build-up formation because of the self-cleaning effect

Integrated automatic sensor detection for transmitters FMU90/FMU95 for simple commissioning

Weather resistant and flood-proof (IP 68)

Hygienic process connections available

Videos

Extended selection

-

High-end products

- Highly functional and convenient

Technical excellence

Simplicity

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

Loading alternative products

Loading alternative products

Predecessor

-

-

Technical Information (TI)

Prosonic S FDU90, FDU91, FDU91F, FDU92, FDU93, FDU95

English version - 01/2018

Ultrasonic measuring technology

EN 25/01/201808/09/201516/01/201302/04/201231/03/2011Language:

English

Version:

25/01/2018

File size:

1013 KB

File name:

TI00396FEN_1818.pdf

-

-

-

Explosion Protection

Product family: Prosonic S

English version - 05/2021

Product root: FDU90-, FDU91-, FDU91F-, FDU92-, FDU93-, FDU95-, FDU96- Region: Europe (ATEX) Approval agency: 2 50 Category: II 2 D, II 2 G, II 1/2 010 Protection: Ex tb IIIC Txxx°C Db , 005 ~ 620 035 060 015, 035 ~ 600 020 025 050, 035 600 020 035 050

Language:

English

Version:

17/05/2021

File size:

7.8 MB

File name:

BVS05ATEXE009e.pdf

-

-

-

Technical Information (TI)

TI Weld-in adapter, process adapter and flanges

Level, pressure and temperature measurement

EN 06/12/202425/03/202415/09/202328/10/202130/07/2021Language:

English

Version:

06/12/2024

File size:

1.3 MB

File name:

TI00426FEN_2624.pdf

-

-

-

Technical Information (TI)

Prosonic S FDU90, FDU91, FDU91F, FDU92, FDU93, FDU95

Ultrasonic measuring technology

EN 25/01/201808/09/201516/01/201302/04/201231/03/2011Language:

English

Version:

25/01/2018

File size:

1013 KB

File name:

TI00396FEN_1818.pdf

-

-

-

Technical Information (TI)

TI Khafagi-Venturi QV302 to QV316

Flow measurement

EN 27/08/202418/05/2022Language:

English

Version:

27/08/2024

File size:

496.2 KB

File name:

TI01681FEN_0224-00.pdf

-

-

-

Technical Information (TI)

FAU40 alignment unit

Installation accessory for ultrasonic or microwave sensors with cable

connectionEN 01/03/202106/09/200501/07/2003Language:

English

Version:

01/03/2021

File size:

446.3 KB

File name:

TI00179FEN_1021.pdf

-

-

-

Technical Information (TI)

Prosonic S FDU91F

Ultrasonic measuring technology

EN 14/09/2020Language:

English

Version:

14/09/2020

File size:

730.6 KB

File name:

TI01471FEN_0120.pdf

-

-

-

Ex Safety Instruction (XA)

Prosonic S FDU90, FDU91, FDU91F, FDU92

II 2 G Ex ma IIC T5 Gb

II 2 G Ex ma IIC T6 GbEN 14/06/202113/04/201631/12/201001/07/200721/08/2006Language:

English

Version:

14/06/2021

File size:

403.2 KB

File name:

XA00321FEN_1521.pdf

-

-

-

Ex Safety Instruction (XA)

Prosonic S FDU90, FDU91, FDU91F, FDU92

II 2 G Ex ma IIC T5 Gb

II 2 G Ex ma IIC T6 GbLanguage:

English

Version:

20/12/2021

File size:

401.3 KB

File name:

XA02642FEN_0121-00.pdf

-

-

-

Ex Safety Instruction (XA)

Prosonic S FDU90, FDU91, FDU91F, FDU92, FDU93, FDU95

II 2 G Ex ma IIC T5 Gb

II 2 G Ex ma IIC T6 Gb

II 1/2 D Ex ta/tb IIIC Txx°C Da/Db

II 2 D Ex tb IIIC Txx°C DbLanguage:

English

Version:

20/12/2021

File size:

416.7 KB

File name:

XA02643FEN_0121-00.pdf

-

-

-

Ex Safety Instruction (XA)

Prosonic S FDU90, FDU91, FDU91F, FDU92, FDU93, FDU95

Ex ma IIC T* Gb

Ex ta/tb IIIC T** Da/Db

Ex tb IIIC T** DbEN 27/06/202222/01/2015Language:

English

Version:

27/06/2022

File size:

429.4 KB

File name:

XA01343FEN_0222-00.pdf

-

-

-

Ex Safety Instruction (XA)

Prosonic S FDU90, FDU91, FDU91F, FDU92

Ex ma IIC T* Gb

EN 27/06/202222/01/2015Language:

English

Version:

27/06/2022

File size:

413.2 KB

File name:

XA01342FEN_0222-00.pdf

-